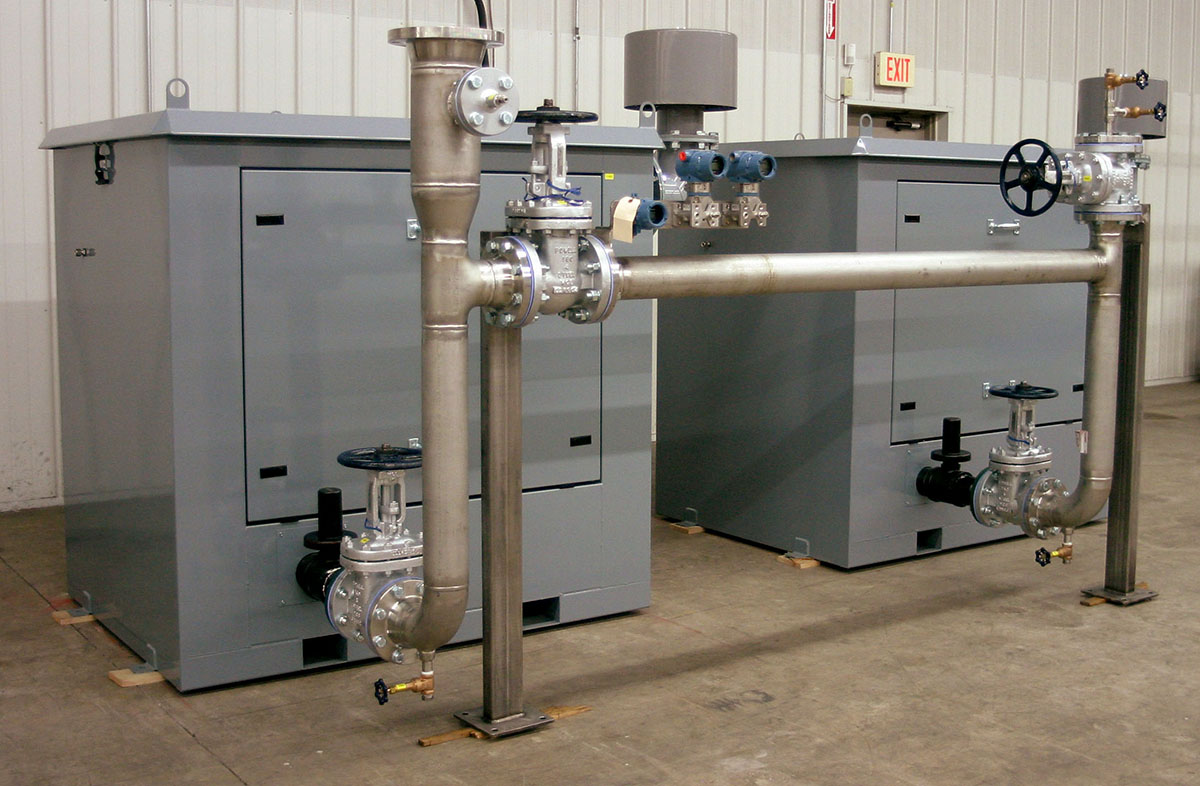

Enclosed Blower Packages

Our SoundSeal blower package sound enclosures provide superior noise reduction with a small footprint.

C. Emery Nelson, Inc. SoundSeal Blower Package systems can be mounted outdoors with no secondary cover. The SoundSeal 54 and 65 are noise reduction enclosures containing a pre-assembled, skid mounted blower units. The SoundSeal 92 enclosure is of drop over design with a freestanding blower package shipped separately.

SoundSeal Design Features:

- Lightweight panels for full access to the Gardner Denver blower, motor and all other accessories inside of the enclosure.

- Maximum sound dBa reduction.

- 3 Standard Sizes 54, 65, an 92 (45L x 54W x 47H, 65L x 49Wx 64H, 92L x 60W x 74H)

- Front mounted pressure gauge, blower and enclosure temperature gauge/switch, and differential filter gauge.

- Powder coated enclosure finish.

- Water tight design for outdoor installation.

- Integral forklift pockets for convenient transportation and handling.

SoundSeal Advantage:

- Bare enclosure available from stock.

- Skid mounted enclosure sizes for 2-6” silencer base combo.

- The 54 and 65 feature removable side panels and roof panel(s) for full access.

- The 92 has double door hinged side access and removable roof panel.

Blower Sound Enclosure Specification (PDF) — CAD Drawings available on request

SoundSeal Standard Equipment:

- Powder coated enclosure finish.

- Water tight design for outdoor installation.

- The best blower for the job, not just a few models available.

- TEFC premium efficient – inverter rated motor.

- Integral silencer base combo.

- Enclosure and blower inlet filters.

- Weight loaded pressure relief valve.

- Check Valve.

- 1/2” rubber enclosure isolation strips.

IQ Family of Blower Packages by Gardner Denver

IQ-RB Package Features

- Tri Lobe Blower

- 15HP-600HP

- Fixed speed packages with inverter duty motors

- Mechanical Gauges

- Patented tunable inlet filter/silencer

- Unique noise enclosure design with double sound insulation panels

- Noise levels under 80 dBa with enclosure

- Automatic belt tensioning and simple belt replacement

IQ Package

Range 7.5 HP- 100HP Factory Direct

Intelligent monitoring solutions – available features via the AirSmart controller

-

- Package Sequencing

- Remote Monitoring –Also Monitors Oil Level, Oil Temp

- Quiet Sound Enclosure (sound levels as low as 60 dBA)

- TEFC EISA premium efficiency Motors less starter is standard

- Removable Discharge Silencer

- Vacuum/Pressure Connections

- Pre-Mounted Valves with Relief and Check Valves standard

- Unloaded start valve optional

- Enclosure Cooling Fan

- Optional Equipment

- Full voltage starter

- VFD

- EMC Filter

- Line Reactor

- Communication Module

- Oil level and temperature sensors

- Removable & hinged panels providing easy access for maintenance

- Premium Vibration Isolators

- Automatic Belt tensioner

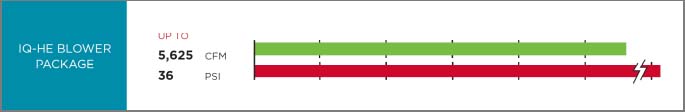

IQ-HE Package Features

-

-

- Patented 3x5 helical screw rotor profile with food grade PTFE coating

- High and low pressure options

- Up to 36psi for dense conveying applications

- Fixed speed packages with inverter duty motors

- AirSmart G2 controller

- Compact design with reduced dimensions and sound insulation panels

- Patented tunable inlet filter/silencer

- Automatic belt tensioning and simple belt replacement

- External oil level gauges

-

Benefits

-

- Reduced number of revolutions and energy consumption in all working conditions.

- Low energy consumption saves up to 30% on energy bills for quick return on investment.

- High Pressure conveying.

- Turndown capability.

- Suitable for intermittent use with frequent stops and restarts.

- Noise enclosure separate from blower = no vibration transmitted to walls.

- Ease of inspection.

- All maintenance operations are performed from the front with removal of panels.

- Oil changes can be performed with easily accessible fill and drain hoses.

- Oil levels can be checked via gauges with or without blower running.

- Minimized downtime and reduced maintenance costs.

- Side-by-Side package installation capability.